Making Manufacturing Processes More Streamlined

Consumers today want more for their money. They see the advances made in recent years and want the latest products at competitive products. Furthermore, they don’t want to wait for these products. To meet these demands, a business must streamline its manufacturing processes.

Many people assume this means a business must automate processes and invest in new equipment. However, smaller changes add up over time. Using lean manufacturing processes, for example, can help move the business forward.

A manufacturer might find getting details about Infor M3 is enough to move them forward when it comes to streamlining processes. This enterprise resource planning software makes them more competitive. What other steps might a business take to simplify operations?

Quality Control

A business can streamline processes and still see a decline in business. Often, this is a result of low-quality products. Quality must be a priority at every stage of the manufacturing process. Consistency in this area keeps costs down while improving customer loyalty.

Increasing the quality of the manufacturing process begins with the raw materials. In addition, the quality must be inspected at each stage of the manufacturing process to see where requirements aren’t being met. If a problem is found, halt the manufacturing process until it is corrected. Catching problems early saves time and money.

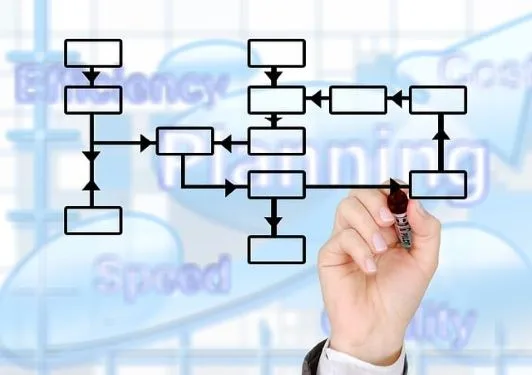

Adopt Key Metrics

A manufacturer might be tempted to track countless metrics and key performance indicators. However, it is best to focus on a select few, choosing those metrics and KPIs most relevant to daily operations. Determine which items are of most importance in tracking the objectives and goals of the organization and use those metrics.

Before doing so, ensure all processes and systems are in place to collect data. This allows all data to be seen in a central location. The dashboard makes it easy to see the interdependencies of the various metrics and KPIs to narrow down which ones are critical to streamlining operations.

Best Practices

To streamline manufacturing processes, an organization must adopt best practices. The practices of most importance in this industry are quality, communication, and reduced waste. Quality was previously discussed.

Communication must be prioritized across all departments. This includes the sale, production, and engineering departments. Furthermore, the organization must minimize waste at all levels. Materials are only one item to be considered when looking at ways to cut waste. The company must also find ways to reduce waste when it comes to time management.

Consider Simplifying Options

While a company may want to offer every product a consumer could want, this extensive product line could lead to production delays. Excessive inventory and expensive customization are two ways a production line may be stalled by the number of products offered. The sales process increases in complexity, and additional steps are added to the production process.

By simplifying the product line, a company can focus on its areas of expertise. Customers come to know the company for what it does best, and the company is able to fine-tune its offerings. This streamlining of the production process allows for better products at affordable prices.

Manufacturers often struggle to maximize their ROI. With the help of the above steps, any manufacturer can improve the efficiency of its operations. Doing so allows for increased profits and improved quality. Furthermore, the company can spend more time focusing on innovation. Learn more today about how to streamline operations in manufacturing to see results in a short period.

Consumers today want more for their money. They see the advances made in recent years and want the latest products at competitive products. Furthermore, they don’t want to wait for these products. To meet these demands, a business must streamline its manufacturing processes.

Many people assume this means a business must automate processes and invest in new equipment. However, smaller changes add up over time. Using lean manufacturing processes, for example, can help move the business forward.

A manufacturer might find getting details about Infor M3 is enough to move them forward when it comes to streamlining processes. This enterprise resource planning software makes them more competitive. What other steps might a business take to simplify operations?

Quality Control

A business can streamline processes and still see a decline in business. Often, this is a result of low-quality products. Quality must be a priority at every stage of the manufacturing process. Consistency in this area keeps costs down while improving customer loyalty.

Increasing the quality of the manufacturing process begins with the raw materials. In addition, the quality must be inspected at each stage of the manufacturing process to see where requirements aren’t being met. If a problem is found, halt the manufacturing process until it is corrected. Catching problems early saves time and money.

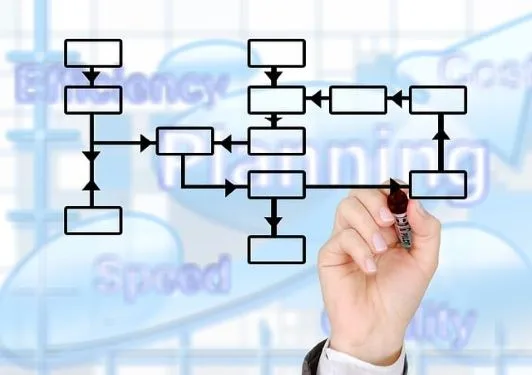

Adopt Key Metrics

A manufacturer might be tempted to track countless metrics and key performance indicators. However, it is best to focus on a select few, choosing those metrics and KPIs most relevant to daily operations. Determine which items are of most importance in tracking the objectives and goals of the organization and use those metrics.

Before doing so, ensure all processes and systems are in place to collect data. This allows all data to be seen in a central location. The dashboard makes it easy to see the interdependencies of the various metrics and KPIs to narrow down which ones are critical to streamlining operations.

Best Practices

To streamline manufacturing processes, an organization must adopt best practices. The practices of most importance in this industry are quality, communication, and reduced waste. Quality was previously discussed.

Communication must be prioritized across all departments. This includes the sale, production, and engineering departments. Furthermore, the organization must minimize waste at all levels. Materials are only one item to be considered when looking at ways to cut waste. The company must also find ways to reduce waste when it comes to time management.

Consider Simplifying Options

While a company may want to offer every product a consumer could want, this extensive product line could lead to production delays. Excessive inventory and expensive customization are two ways a production line may be stalled by the number of products offered. The sales process increases in complexity, and additional steps are added to the production process.

By simplifying the product line, a company can focus on its areas of expertise. Customers come to know the company for what it does best, and the company is able to fine-tune its offerings. This streamlining of the production process allows for better products at affordable prices.

Manufacturers often struggle to maximize their ROI. With the help of the above steps, any manufacturer can improve the efficiency of its operations. Doing so allows for increased profits and improved quality. Furthermore, the company can spend more time focusing on innovation. Learn more today about how to streamline operations in manufacturing to see results in a short period.