Lab Pumps Demystified: A Comprehensive Guide For Health Professionals

Lab pumps are essential tools in any healthcare setting, from hospitals to private practices. They allow you to control the flow of fluids precisely and ensure accurate dosing and delivery of medications, nutrients, and other solutions. However, with so many different types of pumps on the market, figuring out exactly what you need can get confusing. This guide aims to demystify lab pumps so you can find the right one for your unique requirements. The following sections will cover the major categories of lab pumps, key specifications to consider, and provide tips on choosing the best model for your needs.

Types Of Lab Pumps

There are four main types of lab pumps: peristaltic, syringe, centrifugal, and positive displacement. Here’s an overview:

There are four main types of lab pumps: peristaltic, syringe, centrifugal, and positive displacement. Here’s an overview:

- Peristaltic Pumps

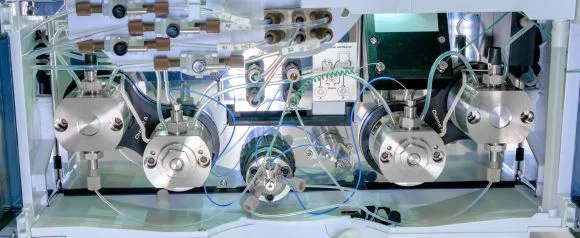

Peristaltic pumps utilize a circular pump head with rotating rollers that compress flexible tubing to create suction, drawing in fluid. As the tube rebounds, the fluid is propelled out the other end in a pulsating wave. This allows aggressive chemicals and abrasive substances to be pumped without contaminating the pump itself. Peristaltic pumps, like the ones you can find on KNF, also offer highly precise and consistent flow rates, making them ideal for dosing applications. Their gentle pumping action suits the handling of delicate particles like cells or tissues as well. Limitations include challenges with higher viscosity fluids and maximum pressure capabilities. Common lab uses include general fluid transfer, dispensing corrosive reagents, cell culturing, and analytical instrumentation feed lines.

- Syringe Pumps

Syringe pumps integrate a lead screw linear actuator to precisely control the movement of a syringe plunger. This allows for incredible control over flow rates, from fast-filling needs down to infusion levels of picoliters per minute. The closed system prevents backflow issues and suits small-volume precision dosing. Syringe pumps can dispense volumes under one microliter reliably. While capacities tend to be lower, multi-syringe models are available. Without a pulsing action, flow is smooth. Limitations include cost scaling with precision level and syringes as consumable components. Syringe pumps excel for analytical sampling, chromatography assays, calibration reagent dosing, and drug development.

- Centrifugal Pumps

Centrifugal pumps utilize an electric motor to spin an impeller inside a housing to create suction, drawing in fluid before accelerating it out of a discharge port. This imparts higher kinetic energy for handling medium to high-flow rate applications. Centrifugal pumps self-prime and handle viscous fluids better than peristaltic models. Lack of pulsation suits filtrations and similar processes. Downsides include less precision control, difficulty pumping at low flow rates, and inability to run dry. Centrifugal pumps suit general fluid transfer applications like emptying tanks and large-scale batch needs. Common lab uses include feeding wash buffers, stripping chromatography columns, and dispensing culture mediums.

- Positive Displacement Pumps

Utilizing mechanisms to physically displace fixed cavity volumes of fluid, positive displacement pumps offer consistent flow unaffected by process pressure changes. This allows handling higher viscosity fluids at higher pressures than other pump types. Flow is smooth without pulsation as well. Downsides include a lack of precision compared to peristaltic and syringe pumps. Some models feature ceramic components enabling aggressive chemical handling. Positive displacement pumps service high-pressure/high-flow analytical instrumentation, autosample injections, chemical transfer lines, and chromatographic separations.

Key Specifications

With the major pump types covered, let’s examine the key specifications you need to consider when selecting a lab pump:

With the major pump types covered, let’s examine the key specifications you need to consider when selecting a lab pump:

- Flow Rate And Pressure Range

Ensure the pump’s flow rate and pressure capabilities match your application needs. More demanding apps require wider ranges.

- Accuracy And Precision

For applications needing exact dosing like HPLC or hitting small sample volumes, precision matters more than accuracy. Precision describes repeatability, while accuracy indicates how close the volume is to the target.

- Tube Sizes

With peristaltic pumps, confirm you accept the tubing diameters you plan to use. Wider tubes permit higher flow rates.

- Contamination Prevention

If pumping toxic chemicals or dealing with sterile solutions, certification like IP65 for water ingress protection is worthwhile.

- Digital Control And Monitoring

Key features that improve convenience and traceability include programmable flow rates, volume tracking, automated dispensing cycles, and app/network connectivity.

Choosing The Best Lab Pump

With a handle on specifications, here are five tips for choosing the optimal lab pump:

- Consider tube, syringe, or pump-chamber materials that suit the compatibility, temperature, and pressure needs of your application.

- Select wetted materials like PTFE that resist corrosion from chemicals you’ll handle.

- Oversize your pump to allow adjustments if process requirements evolve.

- Weigh noise levels if pump location matters. Brushless motor pumps run quieter.

- Seek brands with strong reputations that offer responsive customer support.

Conclusion

We hope this guide has made lab pumps less mystifying! With a clearer picture of the major pump types, critical specifications, and factors to weigh when selecting models, you can zero in on the perfect pump for your unique lab requirements. Investing thoughtfully in the right pumping solution will reward you with seamless, reliable fluid and fluid-handling performance for years of research, testing, and analysis work ahead.